Water Coolers: Latest Technology, Types & Market Trends 2026

Feb 26, 2026

In 2026, the demand for advanced cooling and heating solutions is growing rapidly across residential, commercial, and in...

Read More →

Welcome to Koins Mechatronics, a name that signifies quality, trusted reliability, and advancement within the appliance industry! Koins Mechatronics was found in Sonipat, Haryana in 2009, and has since emerged as a leading producer, supplier, exporter, and dealer of geysers, electric water heaters, ceiling fans, wall fans, and portable air coolers. Thanks to a decade of experience, we are here to help provide energy-efficient, safe long-term solutions for your home, business, and institution.

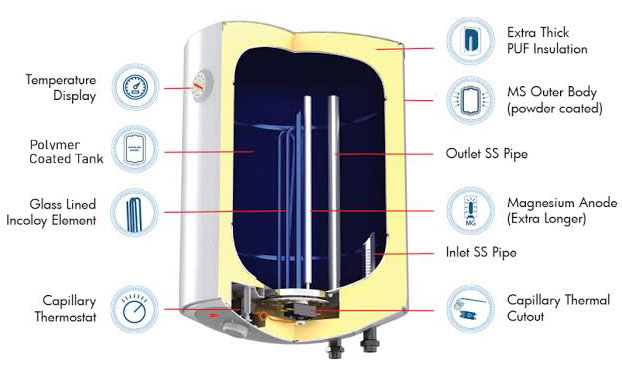

At Koins Mechatronics, we appreciate the role that comfort and convenience play in the modern world. Our electric water heaters and geysers are produced with the latest technology to offer instant heating, lower energy usage, and extended life cycles. We provide everything from household compact options to commercial water heaters for mass-use, you will find an option that suits your needs.

Our products and services are provided to retail customers, wholesalers, OEMs, contractors and government customers. We are bulk manufacturers, custom product developers, and premise developers capable of private labeling and custom development to create market capable solutions.

With a state-of-the-art establishment, along with experienced team, we are focused on precision engineering and continuously and reliably innovating. Our operations are powered by computerized product and die mould designing and in-house tool room for efficient fabricating and maintenance. This combination assures that every geyser, electric water heater and appliance we manufacture is compliant through international certification for performance and safety.

Why Choose Us?

At Koins Mechatronics, we not only manufacture appliances, we build long term customer trust by designing and supplying products built to last our customers an impressive life-time.

Choose Koins Mechatronics for reliable, energy efficient and innovation geysers and electric water heaters.

16

Years of Experience

Koins Mechatronics began its journey with a vision to deliver precise engineering solutions. Initially focused on mechanical components, we built a strong reputation for quality and technical expertise, setting the stage for our future in home appliance manufacturing.

We entered the home appliance industry by manufacturing high-quality geyser parts, from heating elements to stainless steel tanks. Our precision manufacturing and strict quality control standards quickly made us a trusted name in the market.

Building on our success, we diversified into stainless steel kitchen solutions and smart home appliances. Our focus on innovation and durability allowed us to serve a wider customer base, both in residential and commercial sectors.

Today, Koins Mechatronics is at the forefront of smart appliance manufacturing, combining IoT technology with energy-efficient designs. Our mission is to make everyday living smarter, safer, and more sustainable for households worldwide.

As an interior designer, I always seek the best products for my clients. Koins India’s geysers have proven to be reliable.

Koins India has been our trusted supplier for geysers for the past 2 years. Their products are always of the highest quality,

We've been sourcing geysers from Koins India for several of our construction projects, and the quality is always consistent

Koins India is a home appliance manufacturer offering products like electric water heaters, geyser parts, ceiling fans, wall fans, and water coolers.

Yes, Koins India accepts bulk (B2B) orders and also provides private-label and OEM solutions for businesses and contractors.

Koins India is located at B-Block, G.F. Killa No 22/24, Village Bahalgarh, Sonipat, Haryana 131021.

You can call +91 99910 10902 or email koins.mech@gmail.com for customer assistance.

Yes, all Koins India products come with a standard manufacturer’s warranty. The warranty period may vary depending on the product type.

Feb 26, 2026

In 2026, the demand for advanced cooling and heating solutions is growing rapidly across residential, commercial, and in...

Read More →

Feb 04, 2026

With rising temperatures and increasing demand for energy-efficient appliances, cooling solutions have become essential ...

Read More →

Aug 13, 2025

Every big achievement starts with small steps, and Koins Mechatronics is proof of this principle....

Read More →